««««««« Post under construction »»»»»»»

DRAWING MACHINE

– in collaboration with Daniel Castaño –

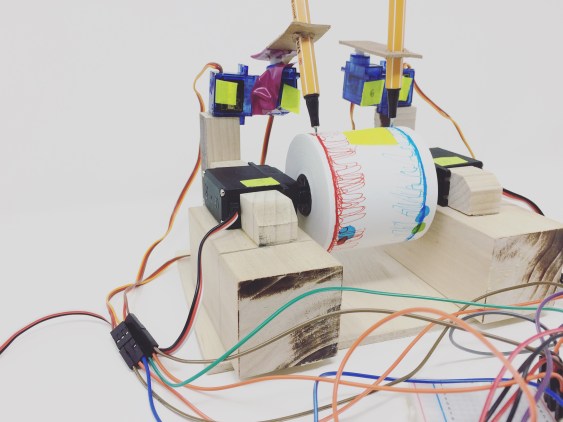

Cardboard, tape and wood prototype

There was an interest from the beginning to make our drawing machine as simple, efficient and budget-friendly as possible, with the paper roll running without much problem on our wood structure, while the main task was to figure how the machine would function properly with all its components, the looks were also very important for us. What works for the deadline? our budget? more components? is this material ok? Because we had many questions we decided that our best course of action was to continue with what we had: glue, tape and cardboard for rapid prototyping. If the code and the structure worked as close as we wanted them to, then we would start cleaning and refining our design.

This prototype had the following materials: Two (2) 360° servo motors – Four (4) micro servos – Two (2) microphones amplifiers – One (1) Paper roll 2 1/4″ – Two(2) Stabilo point pens – One (1) Arduino UNO – One (1) breadboard – Jumpers – Plywood board – Wood board 2 in. x 2 in – Cardboard – Electric tape – Double sided tape – Wood glue.

The biggest issue once we combine all the components was figuring out the degree zero on each micro servo, that piece of information let us know which servo worked better for either the base or the arm. Once we got the degrees we continue with the angles, how far could they go without hitting each other or getting out of the paper roll, this process took a lot of attempts and code debugging.

Another issue we faced was that the base micro servos didn’t work well responding to the microphones at the same time that the arm servos, this meant that once both servos got the signal from the micros, both were moving at the same time. We tried to eliminate this behaviour from the code but the oscillations between the peek of the sounds we always had noise from the base servos. For this time we put them in mute mode while we figure out how to make them work fluidly with the rest of the drawing machine.

Overall our machine was working, the structure itself is very functional and having our electronic components exposed gave it an aesthetic that we appreciate and want to keep exploring. Other discoveries regarding the aesthetic of the drawing machine came from the drawings themselves. While prototyping a lot of repetitions happened (the rolling paper was held in place), noise from the motors (erratic traces), pauses while reloading the code (the ink kept flowing creating little bubbles of colour) and silences (straight traces) from the microphones created artefacts in the drawings.

Final drawing machine materials

Two (2) 360° servo motors – Four (4) micro servos – Two (2) microphones amplifiers – One (1) button – Resistor 220 ohm – One (1) Paper roll 2 1/4″ – Twelve (12) Stabilo point pens – One (1) Arduino UNO – One (1) breadboard – Jumpers – DC Power supply 12 v – M2 x 12mm Screws – M2 Nuts – Screws 1/4 in – Plywood board 12 in x 12 in x 3mm – Wood board 2 in. x 2 in – Acrylic sheet 12 in x 12 in x 3mm – Cardboard – Electric tape – Double sided tape – Magic tape – Wood glue